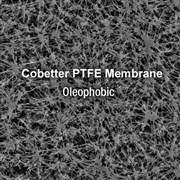

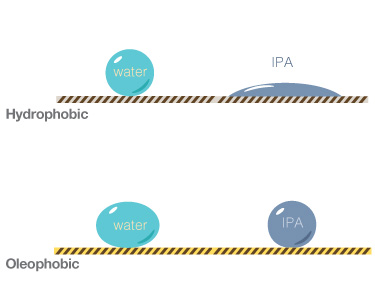

Oleophobic membrane is a super-hydrophobic PTFE membrane modified by hydrophobicity surface treatment (molecular level). Cobetter Oleophobic PTFE membrane meets Oil Rating 8 (AATCC 118 : Oil Repellency: Hydrocarbon Resistance Test), staying hydrophobic against low surface tension liquids like lipids and ethyl alcohol/methyl alcohol.

Surface Tension Comparison of Various Membranes and Solvents

| Material | Surface Tension (Dyn/cm, 20℃) |

| Hydrophilic PES Membrane | >85 |

| 5% NaCl | 77.5 |

| Pure water | 72.8 |

| Hydrophobic PTFE Membrane | 31 |

| Chloroform | 27.1 |

| Acetone | 23.7 |

| Methyl Alcohol | 22.6 |

| Ethyl Alcohol | 22.3 |

| Oleophobic PTFE Membrane | 19 |

Note: 1Dyn/cm=1mN/m

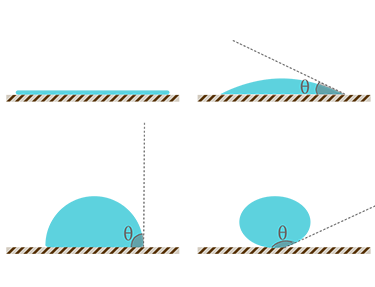

The contact angle is formed between membrane and the tangent to the curve of the liquid droplet. The lower surface tension of the membrane, the greater the contact angle and the easier it is to repel liquid droplets. For example, a 0.2 micron hydrophobic PTFE Membrane could resist 5% NaCl solution as a long term even under certain pressure, but have limited repellent with Ethyl Alcohol. An Oleophobic PTFE membrane could solve this, and perform stable resistance with non-polar liquids, excellent air permeability, and easy to roll off of droplets.

Cobetter hydrophobic PTFE membrane is qualified for common venting cases, but for most of chemotherapeutic medicine infusion venting applications, to secure long duration of non-wetting status and maintain venting function, the vent membrane is required to have a lower surface tension than that of contacting liquidssuch as Docetaxel,Paclitaxel,Etoposide. And Oleophobic PTFE membrane is therefore introduced because of its super low surface tension.

Oleophobic option is necessary for chemotherapeutic medicine delivery venting (Alcohol Repellent), and is also recommended for common venting applications because it offers a longer hydrophobic lifetime, a more secured non-leakage promise, and a higher product safety.Any other application which the membrane might be possibily contact extremely low surface tension liquid (i.e. Surfactant, Oils, Alcohol, Cosmetics, benzene), the Oleophobic PTFE membrane will be a better choice.

Certified Biological Safety (ISO 10993/USP Class VI)

Excellent Air Permeability, Outstanding Air Flow Rates

Optimized Backing Material,Better Sealing Capability

Wide Range of Pore Size (0.02-10μm)

Stable Water Entry Pressure (WEP)

HEPA/ULPA/STERILE Grade

Compatible with Different Sealing Methods

Ultrasonic, Heat, RF Welding, Mechanical, Inserting Molding

Serilization Compatibility

Autoclave,Ethylene Oxide, E-Beam, Gamma Irradiation

Available Pore Sizes (μm)

0.02, 0.03, 0.05, 0.1, 0.2, 0.45, 0.8, 1.0, 2.0, 5.0, 10.0

Typical Performance Characteristics (*0.2μm)

Filtration Efficiency ≥99.99999% Brevundimonas diminuta

Air Flow Rates Gurley 17-49sec

WEP(60s) >450 KPa

Thickness 280-440μm (Supported)

Typical Applications

- IV Filter Vent

- Transducer Protector (TP)

- Bacterial Air Vent

- Sensor Protection Cover

- Package Vents

- Drip Chamber Spike Vent

- Dispensing Pin

- Urine Meters/Bags

- Ostomy Pouches

Support Type

Polyester, Polypropylene, Un-supported

Membrane Formats

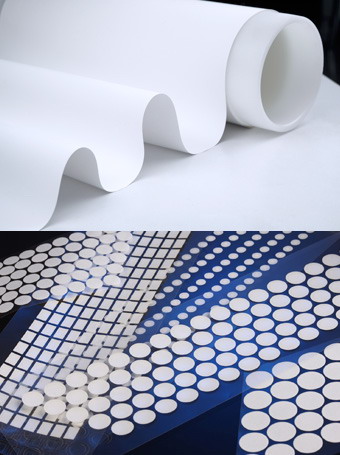

Roll, Sheet, Disc, Adhesive Backing, Customization