- Productos

-

Industrias

- Farmacéutico

- Médico

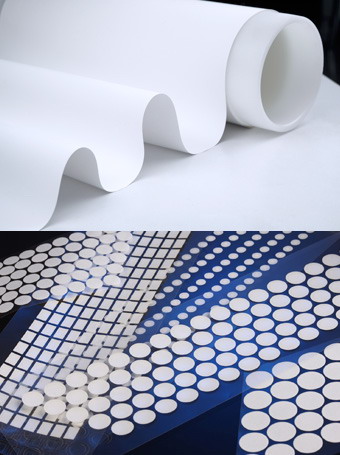

- Membranas y dispositivos OEM

- Membrana de protección del sensor

- Membrana de nylon

- Membrana hidrofílica transpirable

- Membrana de copolímero acrílico

- Membrana de acetato de celulosa libre de tensioactivos (SFCA)

- Membrana de celulosa regenerada (RC)

- Membrana de acetato de celulosa

- Membrana UHMWPE

- Membranas de poliéter de poliuretano sulfona (PES)

- Membrana hidrofóbica de ePTFE

- Membrana oleofóbica de PTFE

- Membrana hidrofílica de PTFE

- Membrana hidrofílica / hidrofóbica de PVDF

- Terapia de infusión

- Filtración de agua médica

- Filtración de aire y ventilación

- Separación de sangre

- Filtro de aire de partículas ultrabajo

- Membranas y dispositivos OEM

- Microelectrónica

- Bebida alimenticia

- Química Fina

- Laboratorio

- Filtros de jeringa

- Membrana de transferencia

- Prueba de microbiología

- Dispositivo de prueba de esterilidad

- Filtro de muestreo de agua subterránea

- Membrana de detección de escape de automóviles

- Membrana de detección del filtro de limpieza del automóvil

- Tubo centrífugo de ultrafiltración

- Membrana de monitoreo de atmósfera / gases de combustión

- Productos

- Últimas noticias

- Sobre nosotros

- Servicios de validación

- Seguro de calidad

- Contacto